Temporary Works

51 Granville Road, Maidstone, UK

Project Brief

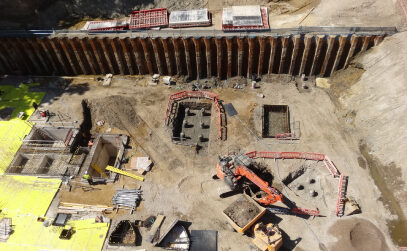

This temporary works project in Maidstone, Kent, involved the construction of a reinforced concrete basement that required propping. The construction sequence on site was such that the temporary propping had to be designed for several load case scenarios. Our remit was the structural design of temporary propping for the basement walls, alongside the design for both the temporary piling platforms and the reinforced concrete slabs for the silo tanks used in the project.

Challenges

Located by a highway, the site required AIP approval before works could commence. The deadlines for approval were critical: if the dates were missed, the construction program would be greatly and adversely affected. The contractor working on the project had a preferred method of propping, which they intended to use to aid their construction sequence on site. After multiple initial design meetings with the construction team and the permanent works engineers, the position of the raking props was agreed.

Process

An initial review of scheme options suggested a traditional structural steel solution to be the best choice for the temporary works. It was crucial to support the high surcharge loading of the 20-ton piling rig operating during the construction phase. However, discussions with the concrete formwork company undertaking the works on site highlighted the suitability of an alternate system. The works team preferred a propriety system that could be constructed quickly, aiding the construction program.

We contacted RMD to discuss their Megashore System, which could support the waler loads from the piling rig, and it was agreed that this was the most efficient solution. While the raking props were spaced so they could be supported by the new pile caps, the new 200mm concrete slab was not able to support the vertical loads. However, by using a waler along the slab to support the raking props, adverse effects on the slab were negated.

Outcome

By adopting this new system – one that neither the contractor, subcontractor nor the LSY team previously used – the project was completed in just one week, and the AIP deadline was met comfortably. Due to the success of Granville Road, we were able to broaden our knowledge and have since utilised this system on other projects.

Back to all projects