New Build

Queen’s Road, Croydon, UK

Project Brief

Our remit was the structural design of seven new build properties alongside the refurbishment of an existing property in the development for our client in Croydon. LSY also undertook site supervision throughout.

Challenges

The new development was surrounded by properties on all four sides, which made access difficult. The only possible entrance was at the front of the site, which influenced the choice of materials in the design process for the construction phase.

Process

The development was to be built on a site where three properties already existed. After these buildings were demolished, LSY undertook an initial site survey shortly after, which included multiple trial holes to confirm the existing boundary conditions. Our survey concluded that the existing boundary walls of the neighboring properties on the side elevations would need to be underpinned traditionally, which was agreed through the party wall process. The ground conditions were then assessed and found to be clay, which meant approximately 1.5 – 2m deep strip footings would be required throughout the site.

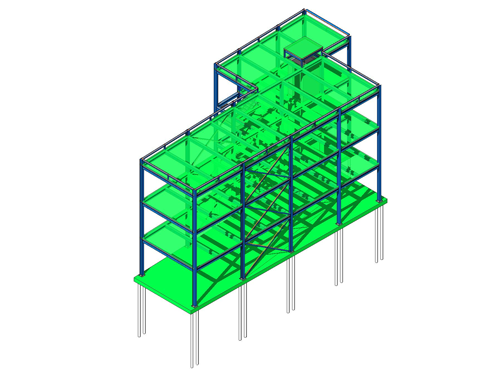

It was decided that the new units would be a hybrid form of construction because of site access issues – a decision that would prove astute during later construction phases. A timber frame scheme with timber I floor joists was chosen for the new build properties. The decision to fabricate the materials off site both sped up the installation process and reduced the number of deliveries to the development. Moreover, only one crane was necessary on site, which reduced the traffic permit requirements for the project. Steel I beams and steel frames were designed to support the structural members in cases where the timber elements didn’t have sufficient capacity to span. The existing on-site property was refurbished by removing several structural walls and lowering the basement.

Outcome

The selection of timber frames proved successful, adhering to the strict site access requirements and increasing the efficiency of construction. As a result, the project was delivered three months ahead of schedule, which allowed the client to sell the units ahead of their initial program plan. The project was also beneficial for LSY, giving our team a crash course in timber frame construction – something we’ve subsequently implemented in similar projects.

Back to all projects